Understanding Crash Ratings

A Guide to Understanding Crash Ratings

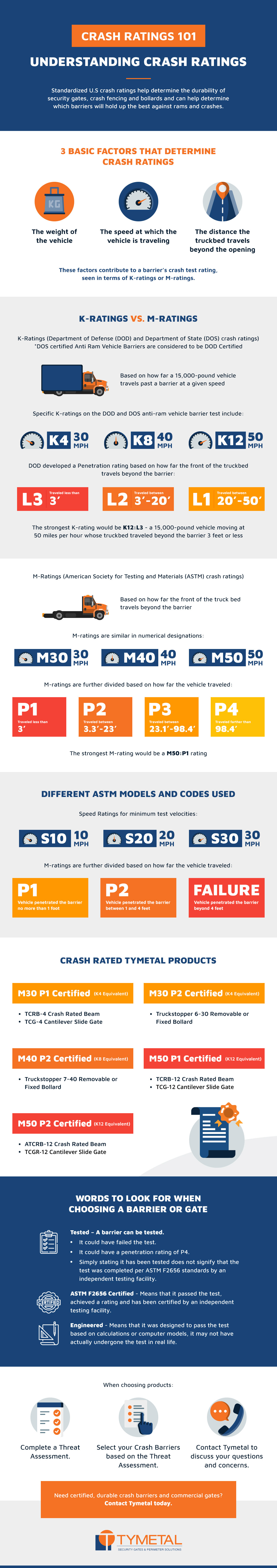

Security barriers and gates play a vital role in protecting entrances from unauthorized access and minimizing damage during accidental vehicle impacts. These systems are essential in modern industrial and defense settings, where safety is a top priority. To ensure the effectiveness of these security measures, standardized crash ratings have been established in the U.S. These ratings provide an objective way to assess how well a barrier can withstand a collision.

Understanding crash ratings is crucial when selecting the right security gate or bollard. By learning how to interpret these ratings, you can make informed decisions that enhance the safety and durability of your security infrastructure. In this guide, we’ll break down the key factors behind crash ratings, explain K-ratings and M-ratings, and clarify the differences between tested, certified, and engineered barriers.

The Three Factors That Determine Crash Ratings

Crash ratings are determined by three main elements:

- The weight of the vehicle involved in the test

- The speed at which the vehicle is traveling during impact

- The distance the vehicle travels beyond the barrier after the collision

Some rating systems only certify barriers up to a certain distance beyond the barrier—anything beyond that is not considered certified. Together, these three factors define the crash rating of a barrier. You may encounter ratings expressed as K-ratings or M-ratings, so it's important to understand the difference between them.

K-Ratings: The Older Standard

K-ratings, developed by the Department of Defense (DOD) since 1985, are based on how far a 15,000-pound vehicle travels past a barrier at a specific speed. A K-rated barrier is certified if the vehicle does not travel more than 50 feet beyond the barrier. Higher K-numbers indicate higher test speeds, with the same vehicle weight and type used for each test. Some common K-ratings include:

- K4: 30 mph

- K8: 40 mph

- K12: 50 mph

K-ratings are further categorized into L1, L2, and L3 based on how far the front of the vehicle traveled beyond the barrier:

- L3: Less than 3 feet

- L2: Between 3 and 20 feet

- L1: Between 20 and 50 feet

The strongest K-rated barrier would be K12:L3, meaning a 15,000-pound vehicle moving at 50 mph penetrated the barrier less than 3 feet. When interpreting K-ratings, the "K" number indicates the test speed, while the "L" number tells you how far the vehicle traveled beyond the barrier.

M-Ratings: The Modern Standard

M-ratings have largely replaced K-ratings in recent years, following standards set by the American Society for Testing and Materials (ASTM). Unlike K-ratings, which focus on how far the front of the vehicle travels past the barrier, M-ratings consider how far the vehicle’s payload penetrates the barrier. Like K-ratings, they are based on vehicle weight, speed, and penetration distance.

M-ratings use a similar numbering system to K-ratings, with corresponding speeds. For example:

- K4 = M30

- K8 = M40

- K12 = M50

M-ratings also include classifications P1, P2, P3, and P4, depending on how far the vehicle traveled beyond the barrier:

- P1: 3.3 feet or less

- P2: 3.31–23 feet

- P3: 23.1–98.4 feet

- P4: More than 98.4 feet

M-ratings offer a broader range of measurements compared to K-ratings, making them more precise. An equivalent to K12:L3 would be M50:P1. Meanwhile, an M50:P2 rated barrier could withstand a 15,000-pound vehicle moving at 50 mph without allowing it to travel more than 23 feet.

Tested vs. Certified vs. Engineered

When evaluating crash-rated products, it's important to understand the difference between “tested,†“certified,†and “engineered.†Each term has its own level of significance:

- Tested: A product labeled as “crash-tested†may not necessarily meet the rating it claims. Just because a barrier was tested doesn’t mean it passed or met the specifications.

- Certified: This label is more reliable. If a barrier is certified at a particular rating, it means it successfully passed the test and achieved that rating.

- Engineered: A product labeled as “engineered†was designed to meet a specific rating using calculations or simulations, but it may not have undergone actual testing.

To ensure quality and reliability, always look for “certified†M- or K-rated barriers. If you see “tested†or “engineered†labels, ask whether the product actually met the specified standards and whether real-world testing was conducted.

Understanding ASTM Models and Codes

ASTM uses models and codes to classify anti-ram tests based on vehicle speed, weight, and penetration distance. These standards help determine the performance of security barriers under different conditions. Here are some key elements of ASTM ratings:

Speed Ratings:

- S10: Minimum test velocity of 10 mph

- S20: Minimum test velocity of 20 mph

- S30: Minimum test velocity of 30 mph

Penetration Ratings (Low Speed):

- P1: Penetration ≤ 1 foot

- P2: Penetration between 1 and 4 feet

- Failure: Penetration > 4 feet

Penetration Ratings (High Speed):

- P1: Penetration ≤ 3.3 feet

- P2: Penetration between 3.31 and 23 feet

- P3: Penetration between 23 and 98.4 feet

These codes help you better understand the performance of a barrier under various crash scenarios.

Choose Certified Security Gates and Barriers from TYMETAL

At TYMETAL, we prioritize security and ensure all our products meet the highest industry standards. Our security gates and crash barriers have achieved prestigious ASTM crash ratings, ensuring they perform reliably in real-world situations. Whether you need durable crash barriers or commercial gates, TYMETAL provides solutions that meet universal safety requirements.

Reviewed By Chris Herold on 4/29/2021

CNC turning is a subtractive manufacturing process in which pieces of material are rotated as a machine tool is fed to the piece, removing material to create a finished piece. It is primarily used to manufacture parts that are cylindrical in nature. We supply custom cnc turning service and CNC turning parts manufacturing

What is CNC TURNING?

Items processed by a lathe will be cylindrical and must be on-centre. Turned parts can range from simple rings to complex curved components. CNC turning is the most efficient way to mass-produce these kinds of parts.

Various cutting tools can be installed within the lathe tooling head to perform different cutting operations sequentially, to produce parts in a one-pass process. Straight cuts, tapers and contours can all be created by varying the angle and depth of the cut.

RongNa CNC Turning system is capable of cutting and holding different types of materials with complete accuracy and efficiency. CNC Turning to manufacture anything from furniture to garden tools to intricate machines and parts for cars and trucks etc.

We are professional CNC Turning Service company and custom CNC Turning Parts manufacturers in China, Our CNC Turning Center help with all kinds of projects and makes cuts of any work piece by changing the angle, the material and the type of cutting tool being used.

Cnc Turning,Cnc Turning service,Cnc Turning Parts,Cnc Turning Services

Ningbo Rongna Technology Co.,Ltd , https://www.service-machining.com