Understanding Crash Ratings

Guide to Understanding Crash Ratings

Bollards and security gates play a crucial role in maintaining the safety and integrity of entry points. They help prevent unauthorized access and reduce property damage from accidental vehicle impacts. In today’s world, where security is a top priority, standardized crash ratings are essential for evaluating the effectiveness of these barriers.

Understanding crash ratings can help you choose the right security gate or bollard for your needs. These ratings provide an objective measure of how well a barrier can withstand a vehicle collision. Whether you're securing a commercial site, a government facility, or a private property, knowing how to interpret these ratings is key to making an informed decision.

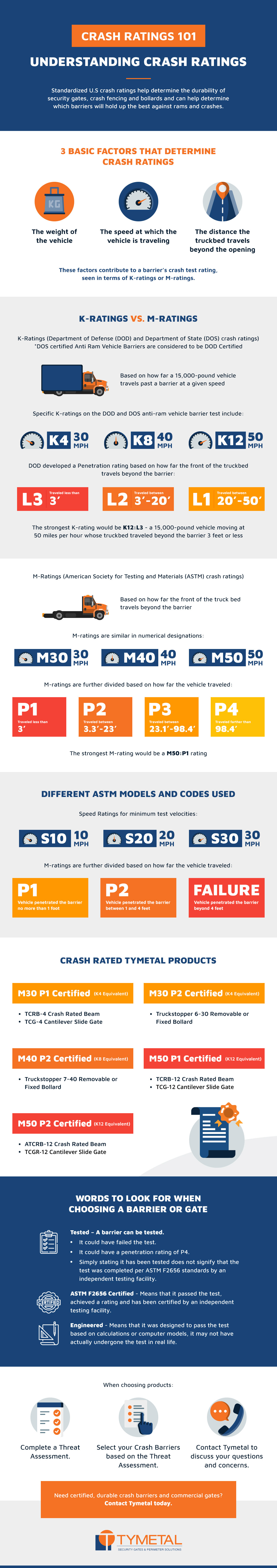

The 3 Factors That Determine Crash Ratings

Three main factors determine the crash rating of a barrier:

- The weight of the vehicle involved in the test

- The speed at which the vehicle is traveling during impact

- The distance the vehicle travels beyond the barrier after the collision

Some rating systems only award certification if the vehicle does not travel more than a certain distance past the barrier. The combination of these three elements defines the barrier's crash rating. You may come across terms like K-ratings and M-ratings, so it's important to understand the difference between them.

K-Ratings: Old Standards

K-ratings, also known as Department of Defense (DOD) ratings, have been used since 1985. These ratings are based on how far a 15,000-pound vehicle travels past a barrier at a specific speed. To be certified, the vehicle must not travel more than 50 feet beyond the barrier. Higher K-ratings correspond to higher test speeds with the same vehicle type and weight.

Common K-ratings include:

- K4: Test speed of 30 mph

- K8: Test speed of 40 mph

- K12: Test speed of 50 mph

K-ratings are further divided into L1, L2, and L3 classifications, depending on how far the front of the vehicle traveled beyond the barrier:

- L3: Less than 3 feet

- L2: Between 3 and 20 feet

- L1: Between 20 and 50 feet

The strongest K-rated barrier would be K12:L3, meaning a 15,000-pound vehicle traveling at 50 mph penetrated less than 3 feet. When reading K-ratings, the "K" number indicates the test speed, while the "L" number shows how far the vehicle traveled beyond the barrier.

M-Ratings: Modern Standards

M-ratings have largely replaced K-ratings and are based on ASTM standards. Unlike K-ratings, which focus on the front of the vehicle, M-ratings consider how far the vehicle's payload travels beyond the barrier. These ratings are similar to K-ratings in that they use numbers to indicate test speeds.

For example:

- K4 = M30

- K8 = M40

- K12 = M50

M-ratings also use classifications P1, P2, P3, and P4 to describe the distance the vehicle traveled beyond the barrier:

- P1: 3.3 feet or less

- P2: Between 3.31 and 23 feet

- P3: Between 23.1 and 98.4 feet

- P4: More than 98.4 feet

M-ratings offer more flexibility in measuring distances, making them more accurate in some cases. An equivalent of K12:L3 would be M50:P1, and an M50:P2 rated barrier could handle a 15,000-pound vehicle at 50 mph without allowing it to travel more than 23 feet.

Tested vs. Certified vs. Engineered

When looking for secure barriers, it's important to understand the differences between “tested,†“certified,†and “engineered.†Each term has a different level of reliability:

- Tested: Just because a product is labeled “crash-tested†doesn’t mean it passed the test or met the specified rating. This label can be misleading.

- Certified: This is the most reliable label. If a barrier is certified at a particular rating, it means it successfully passed the test.

- Engineered: This means the product was designed to meet a specific standard using calculations or simulations, but it may not have undergone real-world testing.

Always look for certified M- or K-ratings when choosing a security barrier. If you see the labels “tested†or “engineered,†ask for proof that the product meets the stated standards. Without real testing, there's no guarantee the product will perform as expected in a real-world scenario.

Different ASTM Models and Codes Used

ASTM uses specific models and codes to classify anti-ram tests based on vehicle speed, weight, and penetration distance. Understanding these codes is essential for interpreting crash ratings accurately.

Key speed ratings include:

- S10: Minimum test velocity of 10 mph

- S20: Minimum test velocity of 20 mph

- S30: Minimum test velocity of 30 mph

Penetration ratings vary by test speed:

- P1 (low speed): No more than 1 foot beyond the barrier

- P2 (low speed): Between 1 and 4 feet

- Failure (low speed): More than 4 feet

- P1 (high speed): No more than 3.3 feet

- P2 (high speed): Between 3.31 and 23 feet

- P3 (high speed): Between 23 and 98.4 feet

These codes help ensure that crash tests are consistent and reliable, providing clear guidelines for evaluating the performance of security barriers.

Buy Certified Security Gates and Perimeters From TYMETAL

At TYMETAL, we understand the importance of high-quality, certified security solutions. All of our security gates and crash barriers meet prestigious ASTM crash ratings, ensuring they adhere to universal, unbiased industry standards.

Shop durable and reliable crash barriers and commercial gates from TYMETAL today. Our products are designed to protect your property and people, offering peace of mind with every installation.

Reviewed By Chris Herold on 4/29/2021

How Does 5-axis CNC MILLING WORK?

Milling is the process of cutting and drilling material using a rotating cylindrical tool. This tool is held in a spindle and comes in a variety of sizes and forms. With 5-axis machining, there have two extra rotary axes defined by A, which rotates around the X axis, B, which rotates around the Y axis, and C, which rotates around the Z axis. The combination of additional axes depends on the machine and comes in variations, including AB, AC, or BC.

With 5-axis machining, the table or cutting tool can be tilted, creating the ability to avoid collision with the tool holder and allowing for better access to part geometry. This also ensures improved tool life and cycle time as it helps maintain cutting position and constant chip load. This type of machining offers a push toward single-setup machining, creating shorter lead times and increasing efficiency.

CNC milling is complex machining technique which utilizes several types of pre-programmed CAM and CNC controls to build customized components or parts. We are professional custom CNC milling company and 5 Axis CNC Milling Service provider in China, we offer the manufacturing of precision machined parts and solutions at affordable rates to meet the growing demands of the clients across the world.

Cnc Milling,Cnc Milling Machine,Desktop Cnc Mill,Small Cnc Mill

Ningbo Rongna Technology Co.,Ltd , https://www.service-machining.com