180 Degree Pipe Elbow

A 180-degree pipe elbow is a crucial component in piping systems, designed to change the direction of liquid or gas flow. It connects two pipes and allows for a complete reversal of the flow path, making it ideal for applications that require a U-turn or a direct opposite direction in the pipeline layout. This type of fitting is commonly used in heat exchangers, industrial systems, and other setups where fluid needs to be redirected efficiently.

Table of contents

- What is a 180 Degree Pipe Elbow?

- Stainless Steel 180 Deg Elbow Dimensions Chart

- SS 180° Elbow Short Radius Size Chart

- 180 Deg Elbow Weight Chart

- DIN 2605 Type 3 180 Deg Elbows Pressure Chart

- Stainless Steel 180 Degree Elbow Tolerances Chart

- Temperature Ratings of 2 Inch 180 Degree Pipe Elbow

- Characteristics of 180 Degree Elbows

- Benefits of 180 Degree Alloy Steel Elbow

- Alloy Steel 180° Elbow Applications

What is a 180 Degree Pipe Elbow?

| Size | ERW / Welded / Fabricated Elbow (1/2″~48″), Seamless Elbow ( 1/2″~24″) |

|---|---|

| Dimensions | ASME/ANSI B16.9 / MSS-SP-43 |

| Thickness | Schedule 5S, 10S, 20S, S10, S20, S30, S100, S120, S140, S160,STD, 40S, S40, S60, XS, 80S, S80, XXS and etc |

| Type | Welded / Fabricated / Seamless / ERW |

| Bending Angle | 180 Degree |

| Ends | Bevel / Plain |

| Form | Long Radius / Short |

| Surface treatment | Shot blasted / Rust-proof / Black oil |

| Material | Stainless Steel / Carbon Steel / Nickel Alloy / Alloy Steel |

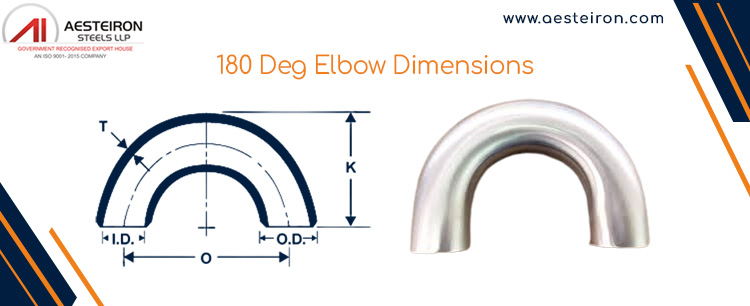

Understanding the Use and Dimensions of 180 Degree Steel Pipe Elbows

180-degree steel pipe elbows are widely used in various industries for their ability to reverse the flow of liquids or gases. They are essential in connecting different parts of a piping system, especially when a full U-turn is required. These fittings are also used in systems that need directional changes, such as in chemical processing, water supply, and power generation. Their versatility makes them a common choice in complex piping arrangements.

They are particularly useful when you need to completely reverse the direction of the flow within a pipeline. This feature makes them ideal for applications where the fluid or gas must be redirected back along its original path, such as in closed-loop systems or when creating a return line.

Stainless Steel 180 Deg Elbow Dimensions Chart

| Nominal Pipe Size | Outside DIA | Wall Thickness | Inside DIA | Center To Center | Back To Face | Weight Pounds | Pipe Schedule |

|---|---|---|---|---|---|---|---|

| 1/2 | 0.84 | 0.109 | 0.622 | 3 | 1.88 | 0.32 | 40 |

| 1 1/2 | 1.9 | 0.145 | 1.61 | 4.5 | 3.25 | 1.6 | 40 |

| 2 | 2.38 | 0.154 | 2.067 | 6 | 4.19 | 3.2 | 40 |

| 2 1/2 | 2.88 | 0.203 | 2.469 | 7.5 | 5.19 | 6.1 | 40 |

| 3/4 | 1.05 | 0.113 | 0.824 | 2.25 | 1.69 | 0.34 | 40 |

| 1 | 1.31 | 0.133 | 1.049 | 3 | 2.19 | 0.74 | 40 |

| 1 1/4 | 1.66 | 0.14 | 1.38 | 3.75 | 2.75 | 1.1 | 40 |

| 3 | 3.5 | 0.216 | 3.068 | 9 | 6.25 | 9.4 | 40 |

| 3 1/2 | 4 | 0.226 | 3.548 | 10.5 | 7.25 | 12.8 | 40 |

| 8 | 8.63 | 0.322 | 7.981 | 24 | 16.31 | 87 | 40 |

| 10 | 10.75 | 0.365 | 10.02 | 30 | 20.38 | 164 | 40 |

| 4 | 4.5 | 0.237 | 4.026 | 12 | 8.25 | 17.5 | 40 |

| 5 | 5.56 | 0.258 | 5.047 | 15 | 10.31 | 29.3 | 40 |

| 6 | 6.63 | 0.28 | 6.065 | 18 | 12.31 | 47 | 40 |

| 12 | 12.75 | 0.375 | 12 | 36 | 24.38 | 237 | * |

| 14 | 14 | 0.375 | 13.25 | 42 | 28 | 311 | 30 |

| 16 | 16 | 0.375 | 15.25 | 48 | 32 | 408 | 30 |

| 18 | 18 | 0.375 | 17.25 | 54 | 36 | 514 | * |

| 20 | 20 | 0.375 | 19.25 | 60 | 40 | 636 | 20 |

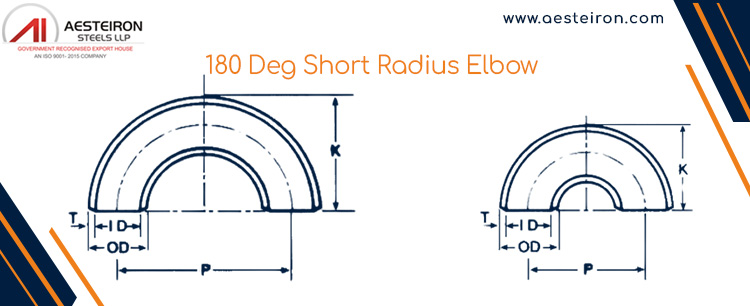

Short Radius 180-Degree Elbows: Compact Design for Space Constraints

Short radius 180-degree elbows are a specialized type of fitting with a smaller bend radius compared to standard 180-degree elbows. The radius of these elbows is typically equal to the pipe diameter, which makes them more compact and suitable for installations with limited space. However, due to the tighter bend, they may cause higher flow resistance and increased pressure drop, which should be considered in system design.

SS 180° Elbow Short Radius Size Chart

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel OD |

Short Radius Elbow | |

|---|---|---|---|

| Center to Center. P |

Back to Face K | ||

| 1-1/4 | 42.2 | 63.5 | 52.3 |

| 1-1/2 | 48.3 | 76.2 | 62.0 |

| 2 | 60.3 | 101.6 | 81.0 |

| 1/2 | 21.3 | – | – |

| 3/4 | 26.7 | – | – |

| 1 | 33.4 | 50.8 | 41.1 |

| 2-1/2 | 73.0 | 127.0 | 100.1 |

| 3 | 88.9 | 152.4 | 120.7 |

| 3-1/2 | 101.6 | 177.8 | 139.7 |

| 10 | 273.1 | 508.0 | 390.7 |

| 12 | 323.9 | 609.6 | 466.9 |

| 14 | 355.6 | 711.2 | 533.4 |

| 16 | 406.4 | 812.8 | 609.6 |

| 4 | 114.3 | 203.2 | 158.8 |

| 5 | 141.3 | 254.0 | 196.9 |

| 6 | 168.3 | 304.8 | 236.5 |

| 8 | 219.1 | 406.4 | 312.7 |

| 18 | 457.2 | 914.4 | 685.8 |

| 20 | 508.0 | 1016.0 | 762.0 |

| 22 | 558.8 | 1117.6 | 838.2 |

| 24 | 609.6 | 1219.2 | 914.4 |

180 Deg Elbow Weight Chart

| Normal Pipe Size In (Inches) | Elbow Short Radius 180 Deg | Elbow Long Radius 180 Deg | ||||||

|---|---|---|---|---|---|---|---|---|

| Sch 5S | Sch 10S | Sch 40S | Sch 80S | Sch 5S | Sch 10S | Sch 40S | Sch 80S | |

| 1/2 | 0.03 | 0.04 | 0.05 | 0.07 | 0.05 | 0.06 | 0.08 | 0.10 |

| 1 1/4 | 0.09 | 0.13 | 0.17 | 0.12 | 0.13 | 0.20 | 0.25 | 0.35 |

| 3/4 | 0.04 | 0.05 | 0.06 | 0.07 | 0.06 | 0.07 | 0.09 | 0.11 |

| 1 | 0.06 | 0.10 | 0.12 | 0.13 | 0.09 | 0.15 | 0.18 | 0.20 |

| 1 1/2 | 0.12 | 0.20 | 0.27 | 0.33 | 0.18 | 0.30 | 0.40 | 0.50 |

| 2 | 0.20 | 0.33 | 0.47 | 0.60 | 0.30 | 0.50 | 0.70 | 0.180 |

| 4 | 0.180 | 1.35 | 2.65 | 3.180 | 1.40 | 2.00 | 4.00 | 5.180 |

| 5 | 1.95 | 2.40 | 4.35 | 6.50 | 2.180 | 3.60 | 6.50 | 9.70 |

| 2 1/2 | 0.40 | 0.60 | 0.180 | 1.20 | 0.60 | 0.85 | 1.35 | 1.80 |

| 3 | 0.60 | 0.180 | 1.35 | 1.180 | 0.180 | 1.30 | 2.00 | 2.180 |

| 6 | 2.70 | 3.35 | 7.00 | 10.5 | 4.00 | 5.00 | 10.5 | 16.0 |

| 8 | 4.180 | 6.70 | 14.5 | 22.5 | 7.40 | 10.0 | 21.5 | 33.5 |

| 16 | 27.5 | 31.5 | 63.5 | 84.0 | 41.3 | 47.0 | 95.0 | 125 |

| 18 | 34.5 | 39.5 | 80.0 | 105 | 51.8 | 59.0 | 120 | 158 |

| 10 | 9.10 | 11.2 | 25.6 | 35.0 | 13.6 | 16.8 | 38.5 | 52.5 |

| 12 | 15.6 | 18.0 | 39.5 | 53.0 | 23.4 | 27.0 | 59.0 | 79.0 |

| 14 | 19.3 | 23.5 | 47.0 | 63.0 | 29.0 | 35.0 | 70.0 | 94.0 |

| 20 | 49.0 | 57.0 | 98.0 | 129 | 73.0 | 85.0 | 146 | 194 |

| 24 | 82.0 | 94.0 | 140 | 188 | 122 | 140 | 210 | 282 |

DIN 2605 Type 3 180 Deg Elbows Pressure Chart

| Service | Pressure Temperature Limits | Pressure Limits |

|---|---|---|

| gases & vapors, Air | maximam 200oF (93oC), min. 0oF (-18oC) |

150 psig (1000 kPa) |

| condensate & Steam | maximam 366oF (186oC), min. 0oF (-18oC) |

150 psig (1000 kPa) |

| Nonflammable Liquids | maximam 250oF (121oC), min. 0oF (-18oC) |

350 psig (2300 kPa) |

Understanding Tolerance Standards for 180 Degree Elbows

Tolerance in 180-degree elbows refers to the acceptable variations in measurements such as wall thickness, diameter, and center-to-center distance. These tolerances are defined by standards like ASME B16.9 to ensure compatibility and safety when integrating these fittings into a piping system. Proper adherence to tolerance limits ensures smooth operation and prevents leaks or structural failures.

Stainless Steel 180 Degree Elbow Tolerances Chart

| All fittings | Elbows 180 degree | 180 degree Returns | |||||

|---|---|---|---|---|---|---|---|

| (NPS) | I.D. at End | O.D. at Bevel | Wall Thick. / t1 | Center to End Dim. A-B-C-M | Back to Face Dim.K | Center to Center Dim.O | Align- ment of EndsU |

| 1/2 a 2 1/2 | 0,8 | 1 | Not | 2 | 7 | 7 | 1 |

| 8 | 1,6 | 2 | of nominal | 2 | 7 | 7 | 1 |

| 10 | 3,2 | +4 -3 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | 3,2 | +4 -3 | 3 | 7 | 10 | 2 | |

| 3 a 3 1/2 | 1,6 | 1 | less | 2 | 7 | 7 | 1 |

| 4 | 1,6 | +2 -1 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | 1,6 | +3 -1 | 87,50% | 2 | 7 | 7 | 1 |

| 20 a 24 | 4,8 | +6 -5 | 3 | 7 | 10 | 2 | |

| 26 a 30 | 4,8 | +7 -5 | 3 | ….. | ….. | ….. | |

| 32 a 48 | 4,8 | +7 -5 | 5 | ….. | ….. | ….. | |

Temperature Ratings of 2 Inch 180 Degree Pipe Elbow

| Pressure-Temperature ratings for ASME B16.9 fittings (psig) | |||||

|---|---|---|---|---|---|

| Temperature Ratings | Pressure Class | ||||

| 150 | 300 | ||||

| 1 1/4 – 2 inch. | 1/4 – 1 inch. | 2 1/2 – 3 inch. | |||

| (oC) | (oF) | ||||

| -29 to 66 | -20 to 150 | 300 | 1500 | 2000 | 1000 |

| 93 | 200 | 265 | 1350 | 1785 | 910 |

| 121 | 250 | 225 | 1200 | 1575 | 825 |

| 149 | 300 | 185 | 1050 | 1360 | 735 |

| 177 | 350 | 150 | 900 | 1150 | 650 |

| 204 | 400 | – | 750 | 935 | 560 |

| 232 | 450 | – | 600 | 725 | 475 |

| 260 | 500 | – | 450 | 510 | 385 |

| 288 | 550 | – | 300 | 300 | 300 |

Characteristics of 180 Degree Elbows

| Type of Elbow | Angle | Purpose | Common Usage |

|---|---|---|---|

| 90-Degree Elbow | 90 degrees | Connects pipes at a right angle. | Most common for sharp turns in piping systems. |

| 45-Degree Elbow | 45 degrees | Connects pipes at a medium angle. | Provides a smoother transition than the 90-degree elbow. |

| 180-Degree Elbow | 180 degrees | Connects pipes to reverse direction. | Used for creating a U-turn in piping systems. |

Stainless Steel 180 Degree Elbows Are Used to Change the Fluid Direction Flow

These elbows are specifically designed to redirect the flow of fluids or gases. They are ideal for situations where a complete U-turn is needed in the pipeline. Whether it's in chemical plants, power stations, or water treatment facilities, 180-degree elbows play a vital role in ensuring efficient and safe flow management.

Benefits of 180 Degree Alloy Steel Elbow

| Aspect | Details |

|---|---|

| Advantage | – No Additional Segments or Fittings: Changes direction without extra parts. |

| – Cost and Time Efficiency: Saves on installation time and expenses. | |

| – Leakage Reduction: Fewer connection points reduce the risk of leakage. | |

| – Reduced Turbulence and Pressure Drop: Smoother flow minimizes turbulence and pressure loss. | |

| Function | – Direction Change: Alters the fluid flow direction in a pipeline. |

| – Pipe Connection: Joins two pipes of the same diameter. | |

| – Flow Adjustment: Provides a 180-degree turn, enabling a complete reversal of flow direction. | |

| Usage | – Applications: Used in various piping systems where a complete change in direction is required. |

SCH 40 180 Deg Elbow Are Widely Used in Oil and Gas and Petroleum Industry

SCH 40 180-degree elbows are known for their durability and strength, making them suitable for medium-pressure environments. With a wall thickness that provides good resistance to stress, these fittings are often used in oil and gas pipelines, refineries, and other industrial settings where reliability is critical. Their design ensures long-term performance under demanding conditions.

Alloy

Hy1 Sintered Small Piece,Injection Molding Machine Screw Barrel,Screw For Injection Molding Machine,Barrel Injection Molding Machine

ZHEJIANG HUAYE PLASTICS MACHINERY CO.,LTD , https://www.hayeur-group.com