The Elios 3 UT Payload: avoiding 15,000 hours of work at height for hull inspections

The Elios 3 UT Payload: Saving 15,000 Hours of Work at Height During Hull Inspections

Key Benefits at a Glance

|

Safety The Elios 3 eliminates the need for work at height, scaffolding, or entering confined spaces, significantly reducing risks during ship hull and tank inspections. |

Speed The Elios 3 can be deployed in under 30 minutes on-site, cutting thousands of hours spent on scaffolding setup and removal. |

|

Localization UT drone surveys with the Elios 3 generate 3D models that make it easy to locate and revisit points of interest for further analysis or maintenance. |

Reporting C-Bird completed the UTM and close-up survey required for the ship’s 5-year inspection, and the data was certified by a class society. |

Every five years, all ships must undergo a special periodical inspection. As ships age, these inspections become more frequent and intense, especially after they reach 15 years old, when major inspections are required every 30 months. These inspections are essential for ensuring a vessel is safe to operate and can be extremely costly due to dry dock time and labor. A key part of the process involves ultrasonic thickness (UT) measurements of the hull and visual inspections of critical areas—especially the midship region, which experiences the most pressure while at sea. These assessments help identify hidden structural issues that might not be visible to the naked eye.

Challenges of Traditional UT Inspections

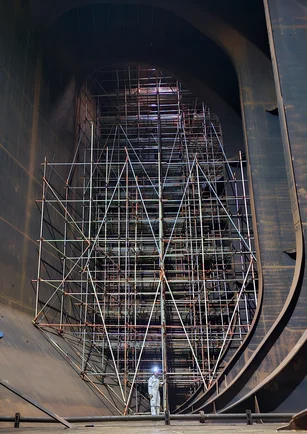

Historically, accessing UT measurement points involved extensive manual labor. Teams of up to 30 people would enter confined spaces and build scaffolding before an inspector could climb and take readings. This method posed significant safety risks, including falls from height and potential damage to the ship if scaffolding components were left behind. Additionally, the process often took days, required permits, and needed the ship to be in dry dock, adding substantial costs. For a 15-year-old tanker, scaffolding alone could cost between $300,000 and $700,000, with the ship out of service for 40–60 days and dry dock fees reaching $4–6 million.

Scaffolding can take thousands of hours and require large teams, posing significant risks and delays.

Scaffolding can take thousands of hours and require large teams, posing significant risks and delays.

C-Bird, a leading maritime inspection company, has been using the Elios 3 for UT inspections on vessels over 15 years old. The drone offers a faster, safer alternative to traditional methods, collecting both UT and visual data efficiently. This approach improves safety standards and reduces the time and cost associated with scaffolding management, speeding up the entire inspection process.

How the Elios 3 Transforms Ship Inspections

C-Bird was tasked with inspecting 12 oil tanks in a medium-sized ship. Using the Elios 3 equipped with its new UT payload, the team conducted both visual and UT inspections. The drone's LiDAR mapping and high-resolution imaging capabilities allowed them to capture detailed visual records without requiring inspectors to climb scaffolding or enter confined spaces. Malcolm Connolly, C-Bird’s CEO and a Flyability product advisor, saw this as a perfect opportunity to test the drone in a real-world NDT environment.

Performing a UT Inspection with the Elios 3

C-Bird used two Elios 3 drones to complete the inspection of the 12 oil tanks. With guidance from a class inspector, they collected UT measurements and visual data in just seven days. The drone’s ability to quickly gather data at the required distance made the process much faster than traditional scaffolding-based methods. After each flight, the pilots confirmed with the class inspector that the spot measurements matched the required locations and quantities.

A close-up view inside one of the cargo oil tanks with the Elios 3.

The Elios 3 streamlined the visual inspection process, allowing the team to collect both visual and UT data in one go. This dual capability cut inspection time in half, as one drone focused on visuals while the other gathered UT measurements. The results included clear visual reports and accurate thickness data, making the process more efficient and reliable.

An example point cloud with UT spot measurements from the Elios 3.

C-Bird compiled the data into the format required by the class society and submitted the report. This method was far more efficient than traditional approaches, eliminating the need to move around scaffolding or adjust MEWPs. The streamlined process saved time, reduced risk, and ensured high-quality results.

Certified Results from the Elios 3

After two years of successful pilot projects, C-Bird and the Elios 3 were officially recognized by the American Bureau of Shipping, one of the world’s leading classification societies, as an approved service provider for ESP hull gauging. This certification marked a milestone, proving the effectiveness of drone-based inspections in the maritime industry.

Watch the Elios 3 use live 3D modeling to guide the drone and take a UT measurement, marking it for reporting.

The Elios 3 delivered five key benefits to C-Bird: precise localization of UT measurements within a 3D point cloud, improved access to confined spaces, reliable and certified results, versatility across multiple environments, and the ability to produce detailed, class-compliant reports. These advantages have positioned C-Bird as a leader in modern, efficient ship inspections.

C-Bird plans to continue using the Elios 3 and its UT payload for inspections across various industries, including maritime, oil and gas, and asset management. The speed, safety, and quality of data achieved through this method mark a new era in challenging and confined space inspections. C-Bird is excited to expand the use of the Elios 3 in future projects, pushing the boundaries of what’s possible in the field of ship inspections.

Discover more about the Elios 3 and its UT payload

Wuxi Qijing Machinery Technology Co., Ltd. , https://www.sinombbrmedia.com