2, the air cylinder should use anti-static flame retardant air duct, the distance from the air duct mouth to the working surface is strictly prohibited more than 5m, and the air volume of the air outlet of the air duct should not be lower than the calculated air volume. The working face should have 4m, 6m, short section of the air duct to ensure that the distance from the air duct mouth to the working surface is not exceeded. 3, the ventilator must be designated to be responsible for the listing management, no one is allowed to stop the fan at will. 4. The local ventilator shall not stop the wind at will; when the wind is stopped due to maintenance or power failure, the personnel must be evacuated and the power supply must be cut off. 5. Gas must be checked before ventilation is restored. The local ventilator can be manually turned on only when the gas concentration in the wind flow within 10 m of the local ventilator and its switch does not exceed 0.5%. 6. The local ventilator stops running for some reason. Before restoring ventilation, the gas must be checked first. Only when the maximum gas concentration in the air-stop zone does not exceed 0.8% and the co2 concentration does not exceed 1.5%, and the above conditions for opening the ventilator are met, The local ventilator can be manually turned on to restore normal ventilation. 7. When the gas concentration in the air-stopping zone exceeds 0.8% or the co2 concentration exceeds 1.5%, and the maximum gas concentration or co2 concentration does not exceed 3%, the following safety measures must be strictly implemented: 1) The discharge gas is organized by the team leader, the gas inspector, the electromechanical maintenance worker and the ventilator. The team leader is responsible for the leadership. The electromechanical maintenance engineer is responsible for the management of the fan operation and the power transmission. The ventilator is responsible for the task of controlling the wind flow. . 2) The gas mixed with the exhaust gas and the full wind pressure air flow shall not exceed 0.8% and the co2 concentration shall not exceed 1.5%. 3), the working face return air system must be powered off and evacuated. 4) Only when the gas concentration in the ventilation of the restored ventilation tunnel does not exceed 0.8% and the concentration of co2 does not exceed 1.5%, the power supply of the electrical equipment in the air supply duct of the local ventilator can be manually restored. The gas concentration in the air-stop zone exceeds 3%. When it is necessary to develop a gas safety measure, report it to the chief engineer for approval. 5) Equipment that cuts off the power supply due to the excessive concentration of gas. When the gas concentration drops below 0.8%, it must be checked and approved by the inspector before it can be manually re-powered. 8. The air cylinder should use anti-static flame retardant air duct. The distance from the air duct mouth to the working surface should not exceed 5m, and the air volume of the air duct outlet should not be lower than the calculated air volume. 9, the air duct must be hung on the ring, there must be a break, and when hanging, it is necessary to rely on the top of the top, not to squeeze and destroy the air duct. To duct linker, linking, using double reverse side, and cinching the intermediate iron wire, so solid and reliable, to prevent disconnection. A special person should always check the hanging of the air duct and find out the problem in time. 10. It is found that the mine car wiper should be disposed of in time, and if necessary, carry out the runway or string shed. 11. It is forbidden for anyone to enter the roadway without wind or warning signs with railings. It is strictly forbidden to work without wind or breeze. It is strictly forbidden to use wind and coal . 12. The two positive and negative dampers of the 1109 yard must be closed frequently. It is strictly forbidden to open the two dampers at the same time. When the pedestrians and the vehicles pass, they must pass a damper to close and then open another damper. The reverse damper should be normally closed. When the excavation work face is fired or an abnormal situation needs to be withdrawn, the last person who withdraws must close the reverse damper (by the team leader and the tile inspector), and the two forward dampers are installed. Locking facilities.

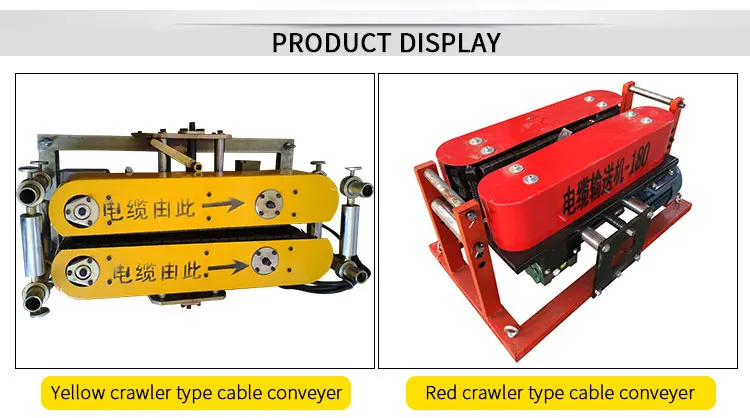

Cable conveyer details:

Usages

DSJ series product is an electric machine for laying power cables (or communication cables).

Packing

Cable conveyer be packed in cartons or pallet.

Applications

Cable conveyer applied in Long distance cable laying.Small volume, light weight, easy to operate.

Features:

1. The two vertical shafts drive the transmission force and gravity respectively in two directions of the cable to protect the insulation of the cable.

2. The transmission force is transmitted through the compound caterpillar, and cater pillar adopts high strength wear-resisting rubber, which make the power force uniform and durable.

3. The machine is equipped with adjustable roller, which is very convenient.

4. The upper part of the machine can be fitted with a hinge wheel, which can be used for small power traction.

5. The machine has low mechanical noise, small temperature rise and easy maintenance.

6. Support products can be provided by user, like –DSJ series electrical control system (total control box, control box) and winding wheel etc.

Data sheet of Cable conveyer:

Cable Conveyer,High Strength Cable Conveyer,Electric Cable Conveyer,Cable Conveying Machine Hebei Long Zhuo Trade Co., Ltd. , https://www.hblongzhuo.com

Model

Advance speed

Range of use

Conveying force

Dead weight

DSJ(G)-150

10.4

Φ60-150

5.5

120KG

DSJ(L)-150

7

Φ60-150

3.8

135KG

DSJ(L)-180

7

Φ60-180

5

160KG

Ventilation and gas safety management measures

1. It is necessary to install the “three specializations and two locks†according to the standardization system of the excavation equipment, install the gas de-energizer, and set up the double-fan dual-power automatic down-down to realize the uninterrupted air supply.