An ore pass is a critical component of underground mining operations, designed to transport valuable ore and waste materials from one level of the mine to another. These vertical or inclined shafts utilize gravity to move materials efficiently, reducing the need for long-distance hauling and improving overall productivity. By providing a direct route between different levels, ore passes help streamline material handling and reduce operational costs. Constructing an ore pass requires careful planning and engineering to ensure its stability, efficiency, and safety. There are two primary methods used to create these structures: the drill and blast technique and the mechanical method using a raise borer. Each approach has its own advantages depending on the geological conditions and mine layout. When designing an ore pass, several factors must be taken into account: Watch this video to see footage from Flyability's Elios drone shot inside an ore pass with a hang-up obstructing it:  In mining, there are two main types of ore pass systems: flow-through and full systems. Both are used to transport ore and waste materials to a draw point, where they are loaded onto conveyors, loaders, or rail cars for further processing or storage. In a flow-through system, ore continuously flows through the pass without accumulating. This setup is ideal when dealing with fine particles that could easily cause blockages. The continuous flow prevents settling and reduces the likelihood of hang-ups. However, this constant movement can lead to increased wear on the pass, requiring more frequent maintenance and possible reinforcements. A full ore pass system maintains a certain amount of material within the pass at all times. This helps prevent degradation and rock failures, but it also increases the risk of blockages due to the accumulation of fines. Managing material levels in this system can be challenging, and longer draw times may be necessary to maintain balance. Maintaining the integrity of an ore pass is crucial for both safety and operational efficiency. Regular monitoring helps identify potential issues before they become serious. Key elements monitored include material levels, wall condition, liner quality, and the performance of material control equipment. Failure to monitor an ore pass can result in blockages, which can halt production, damage equipment, and even endanger miners. Therefore, regular inspections—whether manual or conducted by drones—are essential to keep the mine running smoothly. Blockages in an ore pass can bring mining operations to a standstill. In 2023, a major mining operation in Colorado faced a significant hang-up in an ore pass, preventing any ore from flowing down. Initial attempts to locate the clog were unsuccessful, leading to costly delays and eventually abandonment of the area. The solution came in the form of the Elios 3 drone, which provided real-time visual feedback and a 3D map of the pass. Within minutes, the team was able to pinpoint the location of the blockage and take action. This highlights the growing importance of drone technology in modern mining operations, offering a safer, faster, and more accurate way to inspect and resolve issues in hard-to-reach areas. Within ten minutes, geolocational data on the Elios 3’s 3D Live Map showed them exactly where the clog was located in the raise. You can learn more about how they used the data from the Elios 3 survey to investigate and deal with the ore pass hangup. Lead Glass,X Ray Lead Glass,X-Ray Lead Glass,Lead Glass X Ray Shandong Great Steel Co.,Ltd , https://www.great-steel.comWhat is an Ore Pass in Mining?

Key Considerations When Building an Ore Pass

Types of Ore Pass Systems

Flow-Through Ore Pass System

Full Ore Pass System

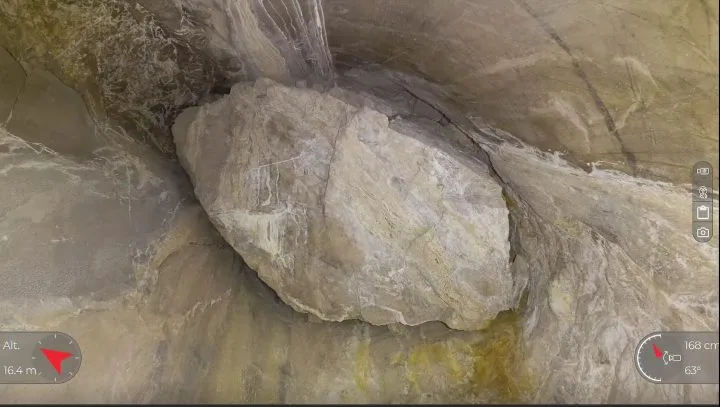

A hang-up in an ore pass

A hang-up in an ore passOre Pass Monitoring

Monitoring the material level in an ore passUsing Drones to Investigate Ore Pass Blockages

What is an Ore Pass in Mining?