An ore pass is a vertical or inclined shaft used in underground mining to transport ore and waste material from one level of the mine to another. It plays a crucial role in reducing the need for long hauls between different levels, making the process more efficient and cost-effective. Ore passes rely on gravity to move materials between different levels of a mine. There are two primary methods for constructing them: the drill and blast method, which involves drilling and blasting to create the pass, and the mechanical method, where a raise borer is used to excavate a circular hole between levels. When planning an ore pass, several factors must be considered: Watch this video to see footage from Flyability's Elios drone inside an ore pass with a hang-up obstructing it: Â There are two main types of ore pass systems used in mining: flow-through and full systems. Both involve dumping ore and waste into the pass, which then flows to a draw point for further transportation. In a flow-through system, ore continuously flows down the pass to the draw point. This system is ideal when there are high levels of fine material, as it prevents settling and reduces the risk of blockages. It is also used when broken rock is processed faster than it is produced, ensuring a steady flow. However, the continuous movement of material increases wear and tear on the pass, requiring regular maintenance and possible reinforcements. A full ore pass system maintains a consistent amount of material within the pass at all times. This helps prevent rock failures and seismic events but increases the risk of hang-ups due to settled fines and oxidation. To manage this, draw times are extended to keep material levels stable. Monitoring an ore pass is essential to maintain its structural integrity, prevent seismic activity, and avoid overfilling. Key elements monitored include material levels, wall quality, liner condition, and the functionality of material control equipment. Regular inspections help prevent blockages and ensure safe operations. Neglecting monitoring can lead to serious consequences, including equipment damage, structural instability, and even injuries or fatalities. Blockages in ore passes can halt mining operations. In 2023, a major mining operation in Colorado faced a significant hang-up that blocked the entire pass. Initial attempts to locate the clog using scanners and cameras were unsuccessful, leading to months of ineffective efforts. The solution came in the form of the Elios 3 drone, which provided real-time visual feeds and 3D mapping capabilities. Within minutes, the drone located the exact position of the blockage, allowing for targeted and effective clearance. With the Elios 3, mine personnel were able to quickly identify and resolve the issue, minimizing downtime and improving operational efficiency. You can learn more about how they used the data from the Elios 3 survey to investigate and deal with the ore pass hangup. Galvanized Steel Plate,4X8 Galvanized Steel Sheets,Hot Dipped Galvanized Steel Plate,Galvanized Steel Base Plates Shandong Great Steel Co.,Ltd , https://www.great-steel.comWhat is an Ore Pass in Mining?

Key Considerations When Building an Ore Pass

Types of Ore Pass Systems

Flow-Through Ore Pass System

Full Ore Pass System

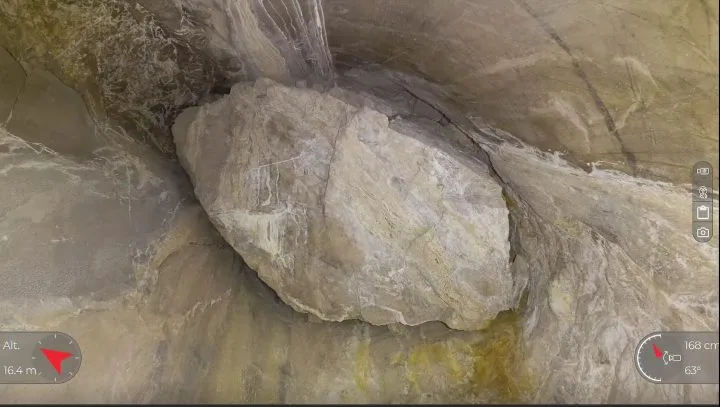

A hang-up in an ore pass

A hang-up in an ore passOre Pass Monitoring

Monitoring the material level in an ore passUsing Drones to Investigate Ore Pass Blockages

What is an Ore Pass in Mining?